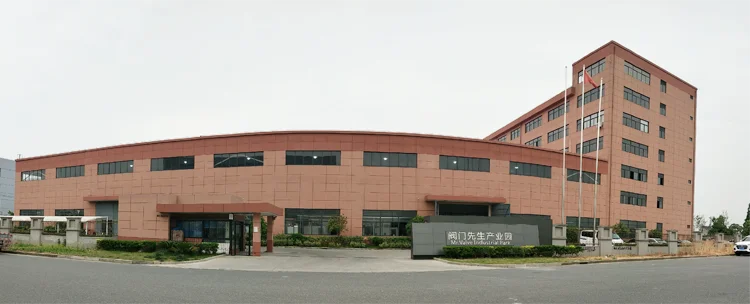

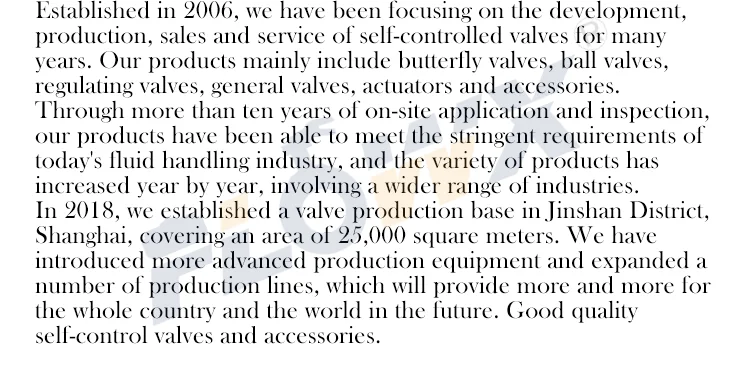

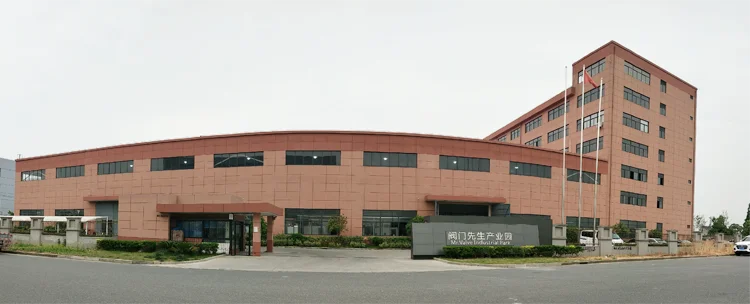

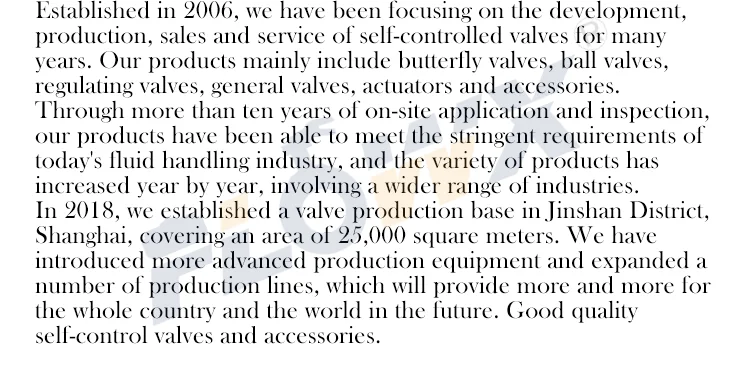

Company introduction:

Related production:

Designed Feature

1. this product mainly used for pumping station,power plant,metallury, paper industry,checmical industry,especially for regulation and control the pipeline flow of drinking water and fluid wasterwater.

2. The product's design in accordance to BS,JSO,ANSI,DIN,JIS.

3. Flange connection in accordance to BS,DINS,ANSI,JIS.

4. Face to face in according to DIN 3202 F4/F5,ISO5752 series 13/14,BS5155.

5. Adopt double eccentric structure can reduce the friction between the sealing ring and sealing belt, minimized operating torque,extended operating life, meet the sealing requirements to realize no leakage.

6. Optimize design displays in: simple structure,light weight,,quick 90 degree on-off operation.

7. Model T sealing ring which matching with plate have a good sealing performance,screws of sealing ring can be adjusted,facilitate replacement and maintenace in line,when working pressure up to PN25,fluid will with a high CV value characteristic to flow through valve plate,high strength and light weight of body.

8. the customers can choose lever,worm gear,pneumatic apparatus,electronic apparatus or combination driving operation according to working requirements.

Solenoid Valve |

DC24V,AC220V,4-20MA |

Nominal Diameter (mm) |

50~1000mm |

Nominal Pressure |

1.0~1.6MPa |

Suitable Temperature |

EPDM:-29℃~+110℃ |

NBR:-29℃~+60℃ |

PTFE: -29℃~+180℃ |

Connection Type |

Double flanged connection Type |

Structure |

Middle-Line |

Body Material |

Ductile Iron with EPDM or PTFE lining |

Carbon Steel with EPDM or PTFE lining |

Stainless Steel with EPDM or PTFE lining |

Disc Material |

304,316,Cast Iron, Bronze |

Seat Material |

EPDM,NBR,PTFE |

Suitable Medium |

Water, oil, slightly corrosive media, etc. |

Additional Parts |

Limit switches, positioners, solenoid valves, air filter reducing valves |

Optional Flanged Butterfly Valve parts Material:

Parts |

Material |

Body |

Stainless Steel,WCB,QT450-10,HT200,HT250 |

Disc |

Stainless Steel,WCB,QT450-10,HT200,HT250 |

Stem |

2Cr13 |

Seal Ring |

Butyronitrile rubber |

Packing |

Flexible graphite |

Exhibition

Packing informations

What is the Connection Standard of our butterfly Valve?

Adoptive Standards

1.Valve Design: API 609, MSS SP-67

2.Face To Face: API 609, MSS SP-67, DIN3202, BS EN558-1

3.Pressure Test: API 598

4.Flange Drilling: ANSI B16.1 class150, BS4504 PN10/PN16, DIN2501 PN10/PN16

Special Test: On request, any other test can be carried out according to special instruction by client.

What is Application of it ?

Application

1.Water Treatment Plant 2.Breweries

3.Drilling Rigs 4. Heating & Air Conditioning

5.Paper Industry 6.Chemical Industry

7.Gas Plant 8.Pneumatic Conveyors

9.Sugar Industry 10.Waste Effluent Treatment Plant

11.Cooling Water Circulation 12.Compressed Air

Application