Take care to ensure that there are no obstacles to the operation and maintenance of the unit at all times. The permissible ambient temperature is 5-40 °C. The device should not be placed under direct sunlight. Outdoor installation requires insulation. When connecting the pipes, make sure that the connections are of the correct size and that they are properly drained without back pressure.

Control Part Structure And Function

The control parts are all controlled by foreign brand electrical components. All device controls are operated on the control box panel.

The metering pump control is manually controlled by the panel or controlled by a timer, and the metering pump stroke is manually adjusted to adjust the flow rate.

Sodium hypochlorite integrated series is an automatic system with chemical solution transport. Its core function is to transfer solution with high precision. The device is suitable for various technical processes, such as Cooling water treatment industry, sewage treatment industry and paper industry, etc.

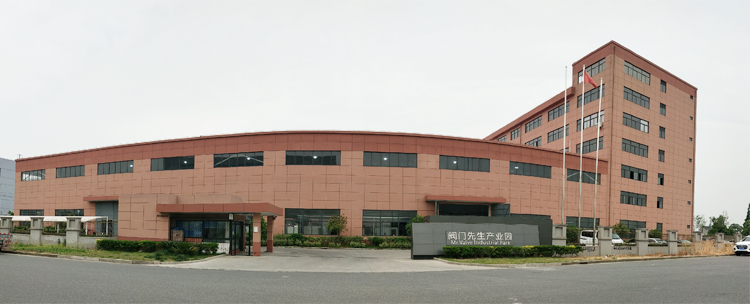

Flowx was established in 2006, we have been focusing on the development, production, sales and service of self-controlled valves for many years. Our products mainly include butterfly valves, ball valves, regulating valves, general valves, actuators and accessories.

Through more than ten years of on-site application and inspection, our products have been able to meet the stringent requirements of today's fluid handling industry, and the variety of products has increased year by year, involving a wider range of industries.

In 2018, we established a valve production base in Jinshan District, Shanghai, covering an area of 25,000 square meters. We have introduced more advanced production equipment and expanded a number of production lines, which will provide more and more for the whole country and the world in the future. Good quality self-control valves and accessories.